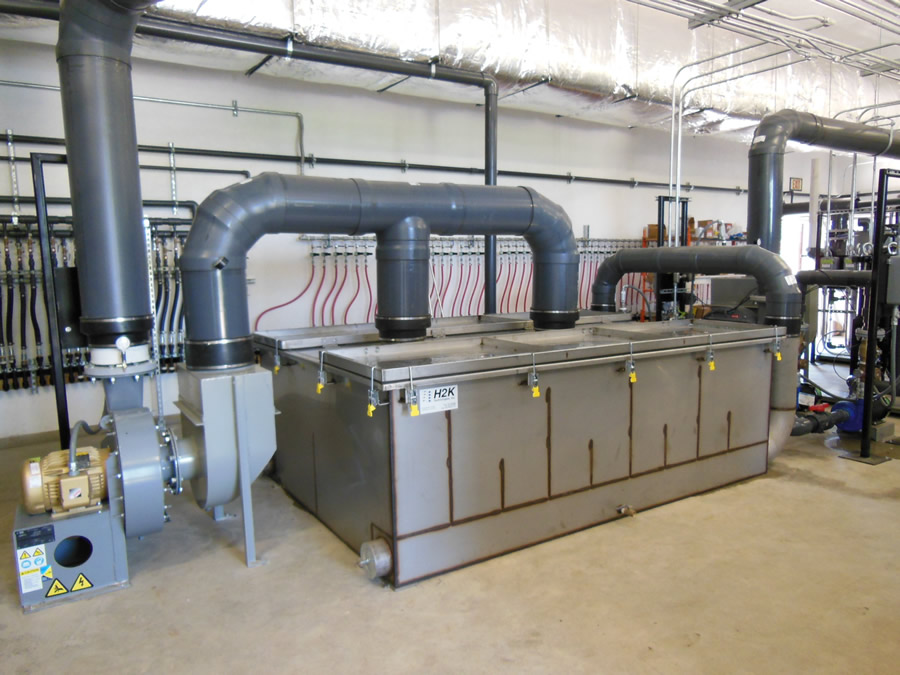

Non-Fouling Air Strippers

H2K manufactures non-fouling air strippers designed to handle high levels of suspended solids, iron, bacteria, and hardness in harsh environments where low maintenance air stripping is of high priority.

Air strippers are used for the removal of volatile organic compounds (VOC), gasoline range organics (GRO) and chlorinated organic compounds from water. Air stripping treatment uses high air to water contact with forced draft air through contaminated water, groundwater or industrial wastewater. The aeration process creates a large mass transfer volume to remove volatile organic compounds from contaminated water. Discharge offgas can be treated with vapor phase carbon vessels, thermal or catalytic oxidizer, or discharged to atmosphere. Air strippers are capable of treating volatile organic compounds like TCE, PCE, vinyl chloride, benzene, toluene, ethylbenzene, xylene, BTEX, and other VOCs to over 99% removal efficiency.

Air strippers are used for the removal of volatile organic compounds (VOC), gasoline range organics (GRO) and chlorinated organic compounds from water. Air stripping treatment uses high air to water contact with forced draft air through contaminated water, groundwater or industrial wastewater. The aeration process creates a large mass transfer volume to remove volatile organic compounds from contaminated water. Discharge offgas can be treated with vapor phase carbon vessels, thermal or catalytic oxidizer, or discharged to atmosphere. Air strippers are capable of treating volatile organic compounds like TCE, PCE, vinyl chloride, benzene, toluene, ethylbenzene, xylene, BTEX, and other VOCs to over 99% removal efficiency.

H2K Technologies DTA Series Air Strippers are the best water treatment choice for VOC removal in environments where inorganic fouling is an issue. Our non-fouling air stripper uses a unique design capable of processing high concentrations of suspended solids, iron, and hardness at peak treatment efficiency. DTA-series air strippers have no trays or packing to foul, which allows continuous VOC treatment even with the heaviest solids loading. Product design includes a set of elevated aerators which allows suspended and precipitated solids to fall below the treatment surface without fouling or plugging. Any inorganic solids and sediment that collect below the aerators is easily cleaned from the air stripper by a single technician without any special tools or lifting equipment. This capacity to handle large amounts of solids keeps air stripper maintenance limited to routine inspections and occasional preventive cleaning.

Air stripping applications

- Industrial wastewater treatment

- Groundwater remediation systems

- VOC water treatment

- BTEX removal (Benzene, Toluene, Ethylbenzene, Xylene, GRO)

- Chlorinated compound removal (TCE, PCE, TCA, Vinyl Chloride, Carbon Tetrachloride)

- Non-fouling air strippers

- Low-maintenance air stripper

- Construction dewatering treatment

- Industrial wastewater

- Portable air stripper systems

Design Considerations

H2K’s non-fouling air stripper design: H2K Technologies manufactures air strippers to avoid the biggest problem that affects stacked trays & towers: fouling and scaling of the treatment surface. Our patent pending design is based on decades of air stripper treatment experience and our knowledge of other products. The high air to water design does not allow any fouling to build up on the air diffusers even during extended use in the heaviest fouling conditions. Our unique air stripper allows sediment and precipitated solids to fall below the elevated aerators without plugging or fouling which maximizes water treatment efficiency. This also minimizes time spent on cleaning & maintenance and keeps the system running effectively without down time for costly cleaning visits.

Easy maintenance: Service and maintenance of our non-fouling air strippers can be handled by a single technician with no specialized tools. The unit is designed with an accessible lightweight cover which allows a single user to easily access all internal components. There are no heavy trays to remove during service visits; the internals are easily removable for any maintenance when needed.

Sizing Considerations

Sizing Considerations

Air stripper sizing is based on several factors:

Henry’s law constant of contaminants: Henry’s constant is a property of a compound which tells how easily a compound will evaporate or strip out of water. Henry’s constant changes with temperature and can vary greatly between different compounds or combinations of compounds. In general, the ability to remove a compound increases with lower values of Henry’s constant.

Concentration of contaminants: Air strippers are able to remove a certain percentage of each contaminant at a given flow rate. In general, a higher contaminant concentration will require a larger air stripper for effective water treatment to meet discharge treatment limits.

Process flow rate: Air stripping treatment is based on residence time and air-to-water ratio. Residence time in the air stripper decreases as water flow rate through the system increases. Applications with higher flow rates require larger size of air strippers.

Discharge location and treatment limits: The final destination of the treated water will affect air stripper sizing. In general, stricter discharge limits (such as for municipal or drinking water applications) require a larger air stripper in order to effectively treat the process flow.

Sample Projects

Corrosive Environment Air Stripper

This custom fiberglass air stripper package was installed in a corrosive wastewater process. Process dealt with very high solids loading and surfactant foaming which required a non-fouling solution. This air stripper system includes inlet/outlet pH adjustment mixer tanks and local control panel with substantial instrumentation.

Mobile Air Stripper System

This mobile water treatment system features an H2K Technologies DTA-series air stripper for groundwater remediation. It was designed to treat benzene at 98% efficiency from 10,000 ppb to 200 ppb discharge limits at 200 GPM. This unit has been in service for 10 years and has been utilized at many sites with high-fouling potential for construction dewatering, remediation, and emergency response.

Transmission Manufacturer

This non-fouling air stripper unit replaced a low profile unit that required an expensive crane lift and multiple people on site for monthly cleaning maintenance. After switching to the DTA air stripper, preventative maintenance visits were reduced to once every 6 months.

Oil & Gas Industry

This non-fouling air stripper package is part of a treatment system capable of handling up to 200 GPM. It was designed to treat benzene, toluene, ethylbenzene, and xylene at over 98% efficiency at 200 GPM. The water treatment package includes blowers, pumps, carbon filters, and controls. This air stripper was chosen for combination of treatment efficiency and limited maintenance visits at this site.